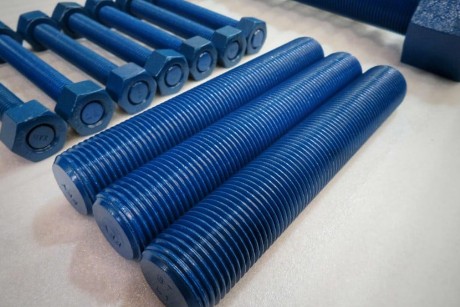

Dry film lubricants or solid film lubricants are materials that reduce friction between surfaces in many extreme environments including those with high and low temperature, high and low pressure and where liquids and oils cannot be used. This coating is an attractive alternative to fluid lubricants for minimizing friction and preventing seizing and galling, especially in high or low temperature environments where fluids may freeze or vaporize. SLA COATING LLC . offers a wide range of lubricant coating options, protecting items from the smallest fasteners to massive industrial components that require a coating to reduce friction. Our solid dry film lubricant coating operation focuses on three types of lubricating materials as below:

Fluoropolymer

Fluoropolymer coatings are superior dry / solid film lubricants that produce a smooth, hard and slick finish.

These coatings are applied using a one coat system that fuses the coating to the substrate for remarkable adhesion. In addition to very low coefficients of friction, fluoropolymers offer exceptional resistance to heat, cold, corrosion and chemical infiltration.

Xylan

Xylan is a combination of low - friction fluoropolymer compounds in a matrix of strong, stabile organic polymers. This fluoropolymer coating exhibits excellent surface wear characteristics along with the resistance to friction, heat, cold, corrosion and chemicals:

Our Xylan coatings offer exceptional resistance to corrosion, abrasion, and chemical exposure.We utilize state of the art technology to apply Xylan coatings, ensuring superior performance and longevity for your components and equipment.

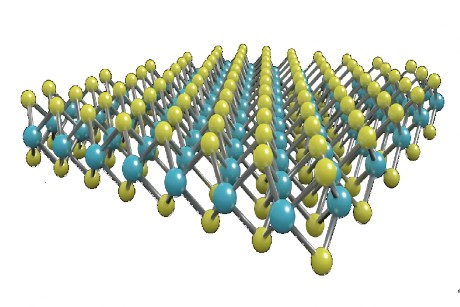

Molybdenum Disulfide

Molybdenum Disulfide, also known as moly dry film lubricant, provides friction protection in high load bearing applications.

The surface of a moly coated item can maintain lubricant qualities up to 250,000 psi. Most MoS2 coatings include additional high-performance resins to enhance bonding to the base metal of the coated part